Digital Twin technology serves as a transformative force in today’s digital landscape, offering a virtual representation of physical entities that bridges the gap between the real and digital worlds. This innovative approach allows for enhanced monitoring, analysis, and optimization of systems across various industries.

As we delve deeper into the intricacies of Digital Twin technology, we will explore its rich historical development, the significant benefits it brings to business operations, and how it relies heavily on data integration for effective implementation. Through real-world examples, we will illustrate how Digital Twin applications are reshaping fields such as manufacturing, healthcare, and urban planning, paving the way for smarter, more efficient processes.

Understanding the concept of Digital Twin technology is essential for grasping its applications in various industries.

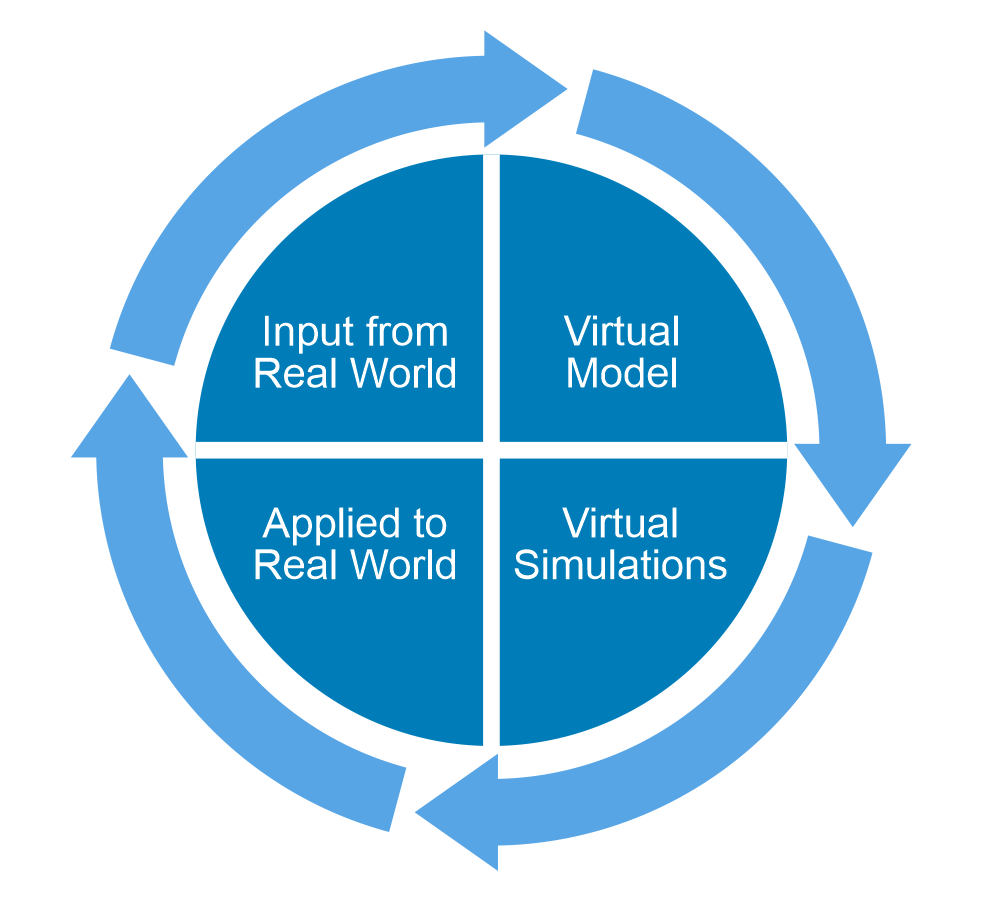

Digital Twin technology represents a significant advancement in the realm of digital innovation, which allows for the creation of virtual replicas of physical entities. This technology enables real-time data monitoring and analysis, bridging the gap between the physical and digital worlds. By simulating the behavior and characteristics of physical assets, Digital Twins facilitate better decision-making, predictive maintenance, and optimize operations across various sectors.

Digital Twin technology can be defined as a digital representation of physical objects or systems, enhanced with real-time data. This entails the integration of multiple data sources, including sensors, IoT devices, and machine learning algorithms. The Digital Twin concept emerged from the aerospace and manufacturing industries, where the need for accurate simulations was paramount. In the early 2000s, the term “Digital Twin” was coined, with NASA utilizing it to improve the management of space missions through precise modeling of spacecraft.

In today’s digital landscape, the significance of Digital Twin technology is profound. It enhances operational efficiency, minimizes downtime, and reduces costs. As industries increasingly embrace Industry 4.0 principles, Digital Twins have become integral in predictive analytics and smart manufacturing. For instance, in manufacturing, companies like Siemens have adopted Digital Twin technology to create virtual models of their production lines, enabling real-time adjustments based on performance data.

Transformative Impact on Industries

The influence of Digital Twin technology extends across several industries, leading to remarkable transformations. Below are examples illustrating its impact:

- Manufacturing: General Electric employs Digital Twins to monitor jet engines, predicting maintenance needs and significantly reducing operational costs. This proactive approach enhances reliability and safety.

- Healthcare: In the healthcare sector, Digital Twins help in patient-specific simulations, such as modeling a patient’s anatomy for personalized surgery planning. This application improves surgical outcomes and reduces recovery times.

- Urban Planning: Cities like Singapore utilize Digital Twin technology to develop smart city solutions. By simulating urban infrastructure, planners can analyze traffic patterns, energy consumption, and optimize resource allocation.

With these implementations, Digital Twin technology not only enhances performance but also opens new avenues for innovation and efficiency, shaping the future of various industries.

Exploring the benefits of implementing Digital Twin technology in business operations is crucial for stakeholder buy-in.

Digital Twin technology has emerged as a transformative force across various sectors, offering innovative solutions to enhance operational efficiency, reduce costs, and improve decision-making processes. As organizations strive to maintain a competitive edge, demonstrating the tangible benefits of this technology is essential for securing stakeholder buy-in. By providing a virtual representation of physical assets, systems, or processes, Digital Twins enable businesses to simulate and analyze performance in real time, leading to more informed and strategic decisions.

Key advantages of Digital Twin technology

Understanding the key advantages of Digital Twin technology is vital for stakeholders who may be hesitant to adopt this innovative approach. Here are three primary benefits that illustrate its value:

- Enhanced Operational Efficiency: One of the most significant advantages of Digital Twin technology is its ability to optimize operational efficiency. By creating a digital replica of physical assets, organizations can monitor performance in real time and identify inefficiencies. For instance, a manufacturing company can use a Digital Twin to analyze the production line’s workflow, pinpointing bottlenecks and areas for improvement. This proactive approach not only reduces downtime but also streamlines processes, ultimately leading to increased productivity. According to a study by Accenture, companies implementing Digital Twin technology have reported up to a 30% reduction in operational costs.

- Cost Reduction through Predictive Maintenance: Digital Twins facilitate predictive maintenance, enabling businesses to anticipate equipment failures before they occur. By utilizing real-time data and analytics, organizations can schedule maintenance activities based on actual usage patterns, rather than relying on a fixed schedule. A notable example can be seen in the aerospace industry, where Rolls Royce employs Digital Twin technology to monitor engine performance. This capability allows them to predict when an engine is likely to require servicing, thus minimizing unplanned downtime and significantly lowering maintenance costs. By implementing predictive maintenance strategies, companies can save millions of dollars annually while ensuring that equipment operates at peak performance.

- Improved Decision-Making Processes: The insights generated from Digital Twin simulations empower stakeholders to make data-driven decisions. With access to real-time data analytics, businesses can evaluate various scenarios and outcomes before implementing changes in the physical environment. For example, in the energy sector, companies can simulate different energy consumption patterns to determine the most efficient operational strategies. This level of analysis enables organizations to identify potential risks and opportunities, fostering a culture of informed decision-making. The ability to experiment in a virtual environment not only accelerates innovation but also mitigates risks associated with new initiatives.

Real-world case studies of Digital Twin integration

Numerous organizations have successfully integrated Digital Twin technology to enhance efficiency and reduce costs. One notable example is General Electric (GE), which has applied Digital Twin technology extensively in its aviation division. GE utilizes digital replicas of jet engines to monitor performance and predict maintenance needs. This implementation has led to actionable insights that reduce maintenance costs and improve operational reliability for airlines, showcasing a clear return on investment.

Another example is the automotive industry, where Ford has adopted Digital Twin technology to streamline its product development process. By creating digital representations of vehicles, Ford is able to test and iterate designs in a virtual space before physical production begins. This not only accelerates development timelines but also allows for cost savings by identifying design flaws early in the process.

In the healthcare sector, Philips has leveraged Digital Twin technology to improve patient outcomes. By using digital replicas of medical devices and systems, Philips can analyze performance data and optimize the functionality of its equipment in real time. This approach has resulted in improved device reliability and reduced operational costs for healthcare providers, demonstrating the broad applicability of Digital Twin technology in enhancing efficiency and reducing costs across various industries.

Insights on decision-making improvements through Digital Twin technology

The integration of Digital Twin technology significantly enhances decision-making processes within organizations. By providing real-time insights and predictive analytics, businesses can make strategic decisions based on comprehensive data rather than intuition or historical analysis. This shift from reactive to proactive decision-making allows organizations to respond swiftly to changing conditions in their environment.

Moreover, the collaborative aspect of Digital Twins fosters cross-departmental engagement, as teams can access the same data and insights. This transparency ensures that all stakeholders are aligned, leading to more cohesive decision-making. For instance, when multiple departments share access to a Digital Twin of a supply chain, they can collectively assess the impact of potential changes and agree on the best course of action. This alignment not only speeds up the decision-making process but also leads to outcomes that are more beneficial for the organization as a whole.

In summary, the implementation of Digital Twin technology in business operations presents significant advantages that can enhance efficiency, reduce costs, and improve decision-making processes. By showcasing real-world case studies and emphasizing the benefits of adopting this innovative technology, organizations can effectively engage stakeholders and drive successful implementation.

The role of data in creating and maintaining effective Digital Twins cannot be overstated.

Digital Twins are virtual replicas of physical entities that rely heavily on accurate and diverse data inputs to function effectively. The creation and maintenance of a Digital Twin hinge on the quality, relevance, and timeliness of the data collected. Without robust data, a Digital Twin cannot effectively mirror its physical counterpart, thus undermining its potential to provide valuable insights and predictive analytics.

Data is the foundation upon which Digital Twins are built, encompassing everything from historical performance metrics to real-time sensor data. The types of data required typically include operational data, environmental conditions, and design specifications. Operational data may consist of machine performance metrics, maintenance logs, and usage patterns, while environmental data refers to external factors like temperature, humidity, and atmospheric pressure that may affect the physical object being modeled. Design specifications ensure that the Digital Twin reflects the original design, including dimensions, material properties, and intended operational settings.

Real-time data collection and analysis impact on accuracy and utility

The accuracy and utility of Digital Twins are significantly enhanced by real-time data collection and analysis. Real-time data provides continuous updates to the Digital Twin, allowing it to adapt dynamically to changes in the physical entity it represents. This adaptability is essential for various applications, such as predictive maintenance, operational optimization, and risk management. For instance, in manufacturing, real-time monitoring of machine health can indicate when equipment is likely to fail, allowing for timely intervention and minimizing downtime.

Integrating real-time data into Digital Twins involves several processes, including data ingestion, processing, and analysis. Data ingestion refers to the collection of data from various sources, such as IoT sensors, operational databases, and external environments. The collected data must then be processed to ensure that it is cleansed, normalized, and formatted for analysis. This processing can involve data aggregation, filtering, and transformation techniques to ensure that the information is usable.

Once the data is prepared, advanced analytical methods, including machine learning algorithms and statistical modeling, are employed to generate insights. These methods allow for the identification of patterns and trends that may not be immediately apparent from raw data alone. The ability to conduct such analyses in real-time ensures that the Digital Twin remains relevant and accurate, enabling organizations to make informed decisions swiftly.

By leveraging both structured and unstructured data sources, organizations can enhance the functionality of their Digital Twins. Structured data typically includes databases and spreadsheets, while unstructured data encompasses a wider variety, such as text, images, and social media content.

Data sources for Digital Twin development

Understanding the different data sources available for Digital Twin development is crucial for maximizing their effectiveness. The following list categorizes potential data sources into structured and unstructured types, highlighting their importance in creating comprehensive Digital Twins:

Structured Data Sources:

– Operational databases: Store detailed records of equipment performance and maintenance.

– ERP systems: Provide insight into supply chain logistics and resource management.

– Sensor data: Collected from IoT devices monitoring various parameters of the physical entity.

Unstructured Data Sources:

– Social media feeds: Offer insights into customer sentiment and market trends.

– Maintenance manuals and documentation: Contain valuable information that can inform the operational parameters of the Digital Twin.

– Images and videos: Capture real-time visual information that can be analyzed for maintenance or operational efficiencies.

By integrating these diverse data sources, organizations can create Digital Twins that are not only accurate representations of physical assets but also powerful tools for operational excellence and strategic decision-making.

Overcoming challenges associated with Digital Twin technology is vital for successful implementation.

The implementation of Digital Twin technology comes with its fair share of challenges that businesses must navigate to achieve success. These challenges can vary widely, from technical hurdles to organizational resistance. Understanding and addressing these obstacles is crucial for organizations aiming to leverage the full potential of digital twins.

Common obstacles businesses face when adopting Digital Twin technology are multifaceted. Some organizations struggle with data integration, as Digital Twins require continuous data flow from various sources, making it essential to have robust data management systems in place. Legacy systems can often hinder integration efforts, leading to fragmented data silos. Additionally, there is a significant skill gap in understanding and utilizing this advanced technology. Many employees may not have the necessary expertise or training, which can lead to ineffective utilization and deployment of Digital Twin systems.

Strategies for Mitigating Challenges

To mitigate these challenges, businesses can adopt several strategies to ensure the seamless integration of Digital Twins within their existing systems. First, investing in employee training and development is critical. By equipping staff with the necessary skills and knowledge, organizations can foster a culture of innovation and adaptability.

Another effective approach is to prioritize a phased implementation strategy. This involves starting with a pilot project where Digital Twin technology is applied to a specific area before scaling it across the organization. This method allows for real-time feedback and adjustments, reducing the risk of large-scale failure.

Collaboration with technology partners can also play a vital role in overcoming implementation hurdles. Partnering with experts who have experience in Digital Twin technology can provide valuable insights and resources, ensuring a smoother transition.

For example, Siemens faced significant challenges when integrating Digital Twin technology into their product lifecycle management. Initially, they struggled with data interoperability between their engineering and manufacturing systems. By adopting a phased approach and collaborating with external experts, Siemens successfully implemented a Digital Twin strategy that improved product design and reduced time-to-market.

Similarly, GE Aviation encountered challenges related to the vast amounts of data generated by its jet engines. To address this, they developed a comprehensive data strategy that emphasized cloud-based solutions for data storage and analysis. This proactive approach enabled them to harness the full potential of their Digital Twin models, ultimately enhancing predictive maintenance and operational efficiency.

Future trends in Digital Twin technology will shape its evolution and applications.

The future of Digital Twin technology is poised for remarkable evolution, driven by advancements in various fields, including artificial intelligence, the Internet of Things, and big data analytics. As these technologies converge, the applications of Digital Twins are expected to expand across multiple sectors, from manufacturing to healthcare, transportation, and smart cities. This transformation promises to enhance operational efficiency, reduce costs, and improve decision-making processes.

One of the most significant emerging trends in Digital Twin technology is the integration of real-time data analytics. This capability allows organizations to simulate and predict outcomes based on current data inputs, facilitating proactive decision-making. For instance, in the manufacturing sector, companies can use Digital Twins to monitor machinery performance, predict maintenance needs, and optimize production processes, thus minimizing downtime and maximizing productivity. Additionally, as 5G networks become more widespread, the ability to transmit vast amounts of data in real time will further enhance the functionality of Digital Twins, enabling more granular and dynamic simulations.

Anticipated implications of Digital Twin trends on businesses and society

The implications of advancing Digital Twin technology are extensive, affecting business operations and societal structures alike. As organizations increasingly adopt Digital Twins, we can anticipate several key changes:

- Enhanced Operational Efficiency: Digital Twins will allow for continuous monitoring and optimization of processes, leading to significant cost savings and productivity gains. For example, companies adopting these technologies may experience up to a 30% reduction in operational costs.

- Improved Product Development: Businesses can leverage Digital Twins to create virtual prototypes, reducing the time and resources needed for product testing and refinement. This shift can lead to faster market entry and heightened competitiveness.

- Informed Decision-Making: Real-time data and predictive analytics will empower organizations to make informed strategic decisions, improving their ability to respond to market changes and customer needs.

- Sustainability Initiatives: Digital Twins can play a critical role in optimizing resource usage and reducing waste, contributing to sustainability goals. For instance, smart city initiatives can utilize Digital Twins to maximize energy efficiency and improve waste management.

- Workforce Transformation: As businesses adopt Digital Twin technology, the demand for skilled professionals in data analytics, machine learning, and system integration will increase, prompting a shift in workforce development strategies.

The societal implications are equally profound, with the potential to transform urban planning, healthcare delivery, and even climate response strategies. For instance, by creating Digital Twins of entire cities, planners can simulate traffic flows, identify bottlenecks, and design more efficient public transportation systems. In healthcare, patient-specific Digital Twins could revolutionize treatment plans by allowing for personalized medical interventions based on real-time health data.

As Digital Twin technology continues to evolve, it holds the promise of not only enhancing business operations but also driving societal innovation, making it a cornerstone of future developments in various sectors.

The interoperability of Digital Twins with other digital technologies is essential for comprehensive solutions.

Digital Twins represent a transformative approach to managing assets, processes, and systems by creating virtual replicas that simulate real-world operations. However, the true potential of Digital Twins is unlocked when they work in conjunction with other digital technologies like IoT, AI, and machine learning. This integration not only enhances the capabilities of Digital Twins but also leads to smarter, more efficient systems that can adapt and optimize based on real-time data and analytics.

The interoperability of Digital Twins with these technologies facilitates comprehensive solutions that can drastically improve decision-making, predictive maintenance, and overall operational efficiency. By leveraging data from IoT devices, Digital Twins can provide a live feed of operational conditions, which AI and machine learning can analyze to identify patterns, forecast outcomes, and recommend actions. This creates a feedback loop where systems continuously learn and evolve, driving innovation and performance improvements.

Integration with IoT, AI, and Machine Learning

The integration of Digital Twins with IoT, AI, and machine learning yields multifaceted benefits across various industries. IoT devices serve as the sensory network, gathering data from physical assets, while Digital Twins act as analytical models that interpret this data. AI and machine learning algorithms then process this information to derive insights and predictive analytics.

The following table categorizes the various technologies that integrate with Digital Twins, highlighting their roles and functionalities:

| Technology | Role | Functionality |

|---|---|---|

| IoT | Data Collection | Provides real-time data from sensors and devices to Digital Twins. |

| AI | Data Analysis | Analyzes data patterns and trends to improve decision-making. |

| Machine Learning | Predictive Insights | Utilizes historical data to forecast future performance and optimize operations. |

| Cloud Computing | Data Storage | Enables scalable storage solutions for vast amounts of data generated. |

| Blockchain | Data Security | Ensures secure and transparent transactions regarding asset data. |

Furthermore, the establishment of standards and protocols is crucial for ensuring smooth communication between these diverse technologies. Standardization enables different systems and tools to work seamlessly together, fostering interoperability. This is particularly important as organizations seek to integrate various technologies into cohesive solutions, making sure that data flows correctly and efficiently across all platforms.

“Interoperability is not merely a technical requirement; it is a prerequisite for achieving the full potential of Digital Twins in an increasingly interconnected world.”

Evaluating the impact of Digital Twin technology on sustainability and environmental initiatives is increasingly relevant.

Digital Twin technology is making waves across various industries, particularly in its role in promoting sustainability and environmental initiatives. By creating virtual replicas of physical assets, systems, or processes, organizations can monitor, simulate, and optimize their operations. This not only enhances efficiency but also allows for better decision-making that aligns with sustainability goals. As the world faces growing environmental challenges, the ability of Digital Twins to contribute to sustainable practices is more important than ever.

Digital Twins can significantly impact industries such as energy, construction, and transportation by enabling more sustainable practices. In energy, they can optimize the performance of renewable sources like wind and solar, thereby maximizing energy output while minimizing waste. In construction, Digital Twins can help in designing buildings that use fewer resources and produce less waste during both construction and operation. Transportation systems can leverage this technology to enhance route planning and reduce emissions, leading to a smaller carbon footprint.

Examples of Digital Twin technology in action

Several companies have successfully integrated Digital Twin technology into their operations, showcasing its potential for reducing carbon footprints and enhancing resource efficiency. These examples illustrate the practical applications of this technology:

- Siemens: Siemens utilizes Digital Twins to optimize wind turbine performance. By analyzing data from virtual models, they can predict maintenance needs and improve energy production, significantly reducing downtime and resource use.

- General Electric (GE): GE employs Digital Twin technology in their jet engines, allowing for real-time monitoring and predictive maintenance. This has led to a reduction in fuel consumption and emissions, contributing to the aviation sector’s sustainability efforts.

- City of Singapore: The city has developed a comprehensive Digital Twin of its urban environment, allowing city planners to simulate and optimize traffic flows, manage resources more efficiently, and reduce greenhouse gas emissions.

- Schneider Electric: By implementing Digital Twins in their critical infrastructure projects, Schneider Electric has been able to analyze energy usage patterns and optimize energy efficiency, effectively lowering the environmental impact of their operations.

The long-term benefits of Digital Twin technology in promoting sustainable development goals are profound. By enabling organizations to make data-driven decisions, this technology fosters a culture of continuous improvement in resource efficiency. Companies that adopt Digital Twins not only enhance their operational efficiencies but also align with corporate social responsibility goals, ultimately contributing to a more sustainable future.

“Digital Twins represent a transformative technology that not only enhances operational efficiency but also drives sustainability initiatives across diverse sectors.”

Closing Notes

In conclusion, the ongoing evolution of Digital Twin technology promises to redefine boundaries and create unparalleled opportunities across industries. As organizations increasingly adopt this technology, they not only enhance operational efficiency but also contribute to sustainability and innovation. The future is bright for Digital Twins, and their integration with complementary technologies will further propel their capabilities, benefiting businesses and society at large.

Frequently Asked Questions

What industries can benefit from Digital Twin technology?

Industries such as manufacturing, healthcare, urban planning, energy, and transportation can greatly benefit from Digital Twin technology due to its capability to enhance efficiency and decision-making.

How does real-time data impact Digital Twins?

Real-time data ensures that Digital Twins accurately reflect the current state of their physical counterparts, allowing for better analysis, predictions, and timely decision-making.

What are the main challenges in implementing Digital Twin technology?

Common challenges include data integration issues, high implementation costs, and the need for skilled personnel to manage and operate Digital Twin systems effectively.

Can Digital Twin technology enhance sustainability efforts?

Yes, Digital Twin technology can significantly contribute to sustainability initiatives by optimizing resource use, reducing waste, and supporting environmental simulations and assessments.

What is the future of Digital Twin technology?

The future of Digital Twin technology looks promising, with advancements in AI and IoT expected to enhance its functionalities and applications, leading to smarter, interconnected systems.