Beginning with Automation, the narrative unfolds in a compelling and distinctive manner, drawing readers into a story that promises to be both engaging and uniquely memorable.

Automation has drastically changed the landscape of industries worldwide, evolving from simple mechanical devices to complex AI-driven systems that enhance productivity and efficiency. This transformation has not only revolutionized manufacturing and service sectors but also ignited discussions on the socio-economic impacts of these technologies on the workforce and our daily lives.

The Historical Evolution of Automation Technologies

Automation technologies have undergone significant transformations since their inception, shaping industries and redefining workflows. From early mechanical devices to contemporary smart systems, the evolution of automation reflects a continuous pursuit of efficiency and precision in various fields. Understanding this historical progression highlights how foundational innovations paved the way for the advanced automation solutions we rely on today.

The journey of automation began in ancient times with simple tools designed to reduce human labor. Key milestones emerged throughout the centuries, showcasing remarkable advancements that have led to today’s sophisticated automated solutions. Early innovations such as the water wheel and the mechanical loom set essential groundwork, allowing for faster production rates and reduced manual effort.

Key Milestones in Automation Technologies

Several pivotal inventions have revolutionized automation practices across different industries, marking significant progress in the field:

- The Water Wheel (circa 4000 BC): One of the earliest forms of automation, the water wheel harnessed natural water flow to generate power for various tasks, such as milling grain and irrigating crops. This innovation laid the groundwork for mechanized processes in agriculture and manufacturing.

- The Mechanical Loom (18th Century): Invented by Jacques de Vaucanson, the mechanical loom allowed for automated weaving, significantly increasing textile production efficiency. This invention played a crucial role in the Industrial Revolution, transforming the fashion industry.

- The Assembly Line (1913): Introduced by Henry Ford for automobile manufacturing, the assembly line revolutionized production by enabling mass production techniques. This method streamlined labor processes and drastically reduced manufacturing costs while increasing output.

- The Programmable Logic Controller (PLC) (1968): Developed by Richard Morley, PLCs transformed industrial automation by allowing machines to be programmed for various tasks. This flexibility made it possible to automate complex processes in manufacturing and other sectors.

- The Rise of Robotics (1980s): The introduction of robotic arms in manufacturing marked a significant advancement in automation. These robots improved precision and efficiency in tasks ranging from assembly to packaging, paving the way for the integration of robotics in diverse fields.

- Artificial Intelligence and Machine Learning (21st Century): The advent of AI has ushered in a new era of automation, enabling systems to learn and adapt. Industries now employ AI-driven solutions for predictive maintenance, quality control, and enhanced decision-making processes.

The historical evolution of automation technologies underscores a consistent theme: the drive to enhance productivity and reduce human error. Each significant invention contributed to a broader understanding of how machines can complement human efforts, ultimately leading to the smart automation we see in industries today.

The Impact of Automation on Job Markets Globally

The advent of automation has significantly transformed job markets around the world. As businesses increasingly adopt advanced technologies, the nature of work is evolving rapidly, creating both opportunities and challenges for the global workforce. This shift is not uniform; rather, its impact varies across different regions and sectors, leading to a complex landscape of job displacement and job creation.

In various regions, the effects of automation have been particularly pronounced in sectors with repetitive, manual tasks. Manufacturing, agriculture, and retail have seen substantial shifts due to the integration of robots and artificial intelligence systems. For instance, in the United States, a study by the McKinsey Global Institute estimated that by 2030, up to 25 million jobs could be lost in the manufacturing sector alone, due to increased automation. However, this same technology is also creating new jobs in sectors such as technology development, system management, and maintenance, illustrating a dual narrative of job displacement and creation.

Regions and Sectors Most Affected by Automation

Understanding which regions and sectors are most impacted by automation is crucial for addressing workforce disparities and developing effective transition strategies. The following points highlight the key areas affected:

- Manufacturing: In advanced economies, the shift towards automation has led to significant reductions in manufacturing employment, particularly in regions reliant on traditional manufacturing jobs.

- Agriculture: Automation in agriculture, including the use of drones and automated machinery, has improved efficiency but also reduced the need for manual labor, impacting rural job markets.

- Retail: The rise of e-commerce and automation in inventory management has transformed retail, leading to job losses in traditional retail roles while creating opportunities in logistics and online operations.

- Transportation: The development of autonomous vehicles is set to disrupt driving jobs globally, with estimates suggesting significant job losses in the taxi and trucking sectors.

The implications for workers in these sectors are profound. Many face the challenge of reskilling or upskilling to remain relevant in an automated workforce. The World Economic Forum predicts that by 2025, 85 million jobs could be displaced by automation, but 97 million new roles more adapted to the new division of labor may emerge.

“Automation is not the enemy; it is a tool that can reshape our workforce and create new opportunities.”

Statistics further illustrate the complex relationship between job displacement and job creation. For example, in Germany, the introduction of industrial robots has led to a 20% increase in productivity, but it has also resulted in a notable decline in low-skill jobs. Conversely, countries like South Korea have seen a relatively balanced outcome where automation has led to job creation in tech-related fields, even as traditional jobs diminish.

These examples underscore the necessity for active workforce planning and support systems to help workers transition through these changes, ensuring that the benefits of automation can be shared equitably across society.

Automation’s Role in Enhancing Productivity

In today’s fast-paced manufacturing and service industries, the integration of automation has become a game-changer for enhancing productivity. Automation tools streamline processes, reduce human error, and optimize resource management, leading to significant improvements in output quality and operational efficiency. Organizations leveraging these technologies are able to respond more swiftly to market demands and improve their overall competitiveness.

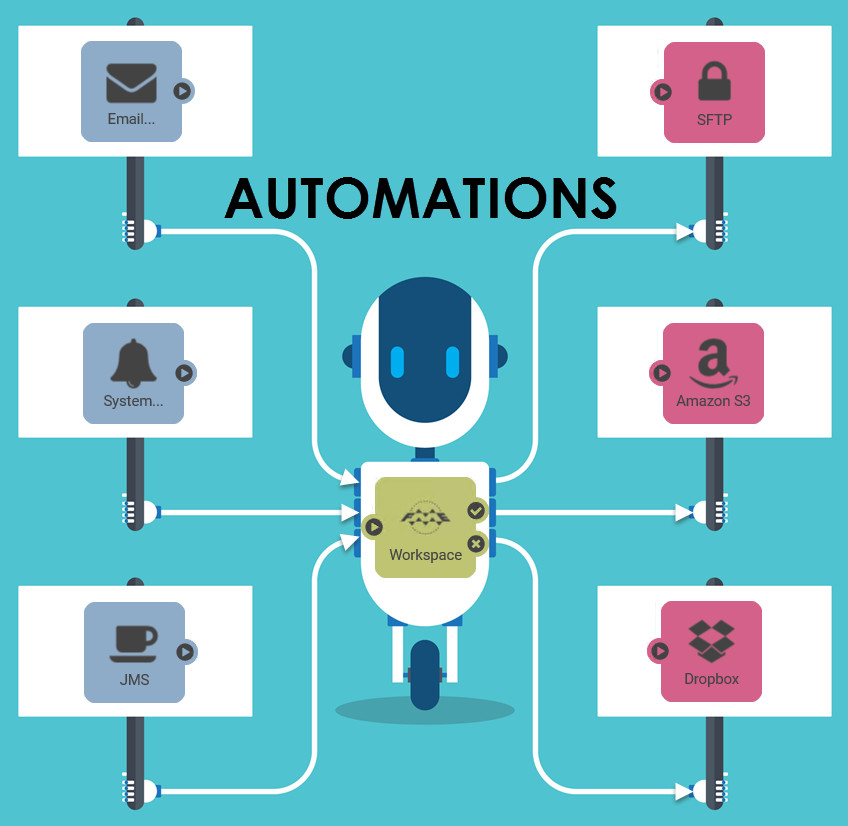

Automation techniques vary widely, each contributing uniquely to productivity enhancements. Key methods include robotics, process automation, and data analytics. These techniques have proven successful in various contexts, transforming how businesses operate by minimizing manual intervention and increasing the speed of production and service delivery.

Successful Automation Techniques in Various Industries

Understanding the most effective automation techniques is vital for businesses looking to boost productivity. Here are several approaches that have demonstrated measurable results:

- Robotic Process Automation (RPA): RPA software allows businesses to automate repetitive tasks such as data entry and invoice processing. For example, companies like UiPath have been instrumental in helping organizations reduce processing times by up to 80% while minimizing errors.

- Manufacturing Robotics: In manufacturing, robotic arms are widely used for assembly, painting, and packaging. For instance, automotive giants like Ford and Tesla have incorporated advanced robotics in assembly lines, enabling them to increase production rates significantly without compromising quality.

- Smart Inventory Management: Automation tools that utilize Internet of Things (IoT) technology facilitate real-time inventory tracking and management. Businesses such as Amazon employ automated systems that optimize stock levels, reducing both excess inventory and stockouts.

- Data Analytics and AI: Utilizing data analytics, companies can streamline operations by predicting trends and making informed decisions. For instance, predictive maintenance powered by AI helps manufacturers preemptively address equipment failures, thereby minimizing downtime and maintenance costs.

Comparing automated processes to traditional methods highlights the substantial benefits automation brings. Automated systems operate with greater precision, effectively managing resources such as time, labor, and materials. In contrast, traditional methods often lead to variability in output and higher operational costs due to inefficiencies. For example, while a traditional assembly line may take hours to produce a set number of units, an automated line can accomplish the same task in significantly less time with a consistent quality level.

“Automation is not just about replacing human labor; it’s about enhancing human capabilities and driving efficiency.”

Organizations that embrace automation not only improve their productivity metrics, but they also create a more agile and resilient workforce capable of adapting to the ever-evolving demands of the market.

The Ethical Considerations Surrounding Automation

The rise of automation technologies in various industries raises significant ethical dilemmas that affect society at large. With advancements in artificial intelligence and robotics, the conversation around automation is no longer just about efficiency and productivity; it also encompasses the moral implications of replacing human labor and the responsibilities that come with deploying such technologies.

The implementation of automation presents a dual-edged sword of potential risks and rewards on a human level. On one hand, automation can lead to increased productivity, efficiency, and safety in the workplace. On the other hand, it poses a risk of job displacement, widening income inequality, and a potential erosion of skills among the workforce. As such, it is crucial to navigate the ethical landscape of automation thoughtfully and responsibly.

Ethical Dilemmas in Automation

The ethical dilemmas surrounding automation are numerous and complex. The discussion encompasses various aspects, including job security, accountability, and societal impact. Here are key considerations:

- Job Displacement: As machines and software take over tasks traditionally performed by humans, the threat of job loss looms large. Industries such as manufacturing and customer service have already seen significant shifts due to automation.

- Income Inequality: The benefits of automation often accrue to business owners and investors, leaving low-wage workers vulnerable. This can lead to a widening wealth gap and increased social tensions.

- Skill Erosion: As automation takes over routine tasks, workers may lose valuable skills, making it difficult for them to find new employment opportunities in an evolving job market.

- Decision-Making Accountability: Automated systems, particularly those driven by AI, can make decisions that affect human lives. The question arises: who is responsible when an automated system makes a mistake?

“The impact of automation is not just a technological issue; it is a societal challenge that requires ethical consideration and proactive management.”

Insights on Responsible Integration of Automation

Experts emphasize the importance of a balanced approach to integrating automation into the workforce. This involves not only maximizing the benefits of technology but also addressing the ethical implications. Key insights from thought leaders in the field include:

- Reskilling and Upskilling: Organizations must invest in training programs to help employees adapt to new technologies and roles created by automation.

- Inclusive Policy Making: Policymakers should craft regulations that promote equitable access to the benefits of automation while protecting vulnerable workers.

- Human-Centric Automation: Companies are encouraged to design automated systems that enhance human capabilities rather than replace them, fostering collaboration between humans and machines.

- Ethical Frameworks: Establishing ethical guidelines for AI and automation deployment can help mitigate risks and promote transparency in decision-making processes.

“A responsible approach to automation considers the long-term implications for society, ensuring technology serves as a tool for empowerment rather than displacement.”

Future Trends in Automation Technology

The landscape of automation technology is evolving rapidly, driven by advancements in artificial intelligence (AI) and machine learning (ML). These innovations are not only transforming industries but are also reshaping the way businesses operate and engage with customers. As we look to the future, several key trends and tools are emerging that will define the next decade of automation.

One of the most significant trends is the increasing integration of AI and ML in automation processes. These technologies enable systems to learn from data, improve decision-making, and enhance efficiency without human intervention. As organizations adopt these capabilities, the potential for automation expands, impacting various sectors, including manufacturing, healthcare, and services.

Emerging Trends in Automation

Several trends are gaining momentum in the field of automation, particularly influenced by AI and ML advancements. It’s essential to understand these trends to grasp their future implications.

- Robotic Process Automation (RPA): RPA continues to evolve, allowing businesses to automate repetitive tasks at scale, reducing human error and operational costs.

- Intelligent Automation: By combining RPA with AI capabilities, intelligent automation can handle more complex tasks, such as customer service inquiries and data analysis.

- Hyperautomation: This refers to the use of advanced technologies to automate processes end-to-end, integrating automation across various business functions.

- Digital Twins: A digital twin is a virtual representation of a physical object or system. This technology is becoming crucial in industries like manufacturing for simulations and performance monitoring.

- Edge Computing: As automation tools become more data-driven, edge computing enables real-time data processing closer to the source, enhancing speed and efficiency.

The societal implications of these trends are profound. For instance, the rise of intelligent automation can lead to significant job displacement in certain sectors, prompting discussions around upskilling and workforce transition. However, it also creates opportunities for new job roles focused on managing and improving automated systems.

Cutting-edge Automation Tools and Techniques

Innovation in automation tools is essential for businesses looking to stay competitive. As industries adopt these tools, it’s crucial to recognize which ones are gaining traction.

- UiPath: A leader in RPA, UiPath provides a platform that allows organizations to automate repetitive tasks efficiently.

- Automation Anywhere: This tool offers RPA capabilities with an emphasis on integrating AI for smarter automation solutions.

- Blue Prism: Known for its robust security features, Blue Prism focuses on enterprise-level automation, enabling businesses to implement comprehensive automation strategies.

- Zapier: This tool connects various web applications and automates workflows, making it ideal for small businesses and startups.

- TensorFlow: As an open-source ML framework, TensorFlow allows developers to create sophisticated AI models that can be integrated into automation processes.

These tools showcase the potential for businesses to enhance productivity, reduce costs, and improve user experiences. As we move forward, the intersection of automation with AI and ML will continue to drive innovation across various sectors, shaping the future of work and technology.

Case Studies on Successful Automation Implementation

Automation has become a pivotal strategy for organizations aiming to enhance efficiency, reduce costs, and improve overall profitability. Numerous companies across various sectors have successfully integrated automation into their operations, overcoming challenges and achieving significant outcomes. The following case studies illustrate the journey of these organizations, the obstacles they faced, and the results they attained through automation.

Manufacturing Sector: Tesla, Inc.

Tesla, a leader in electric vehicle manufacturing, exemplifies successful automation integration. The company faced challenges related to production scale, quality control, and the complexity of its innovative designs. To improve efficiency, Tesla implemented advanced robotics in its manufacturing plants, streamlining assembly line processes. By employing robots for repetitive tasks, the company minimized human error and increased production speed.

The measurable outcomes of Tesla’s automation strategies include a significant reduction in production time per vehicle and a notable increase in output. For instance, the deployment of automated systems allowed Tesla to ramp up production from approximately 2,000 vehicles per week to over 5,000 in a matter of months. This enhanced capacity led to increased market share and profitability, demonstrating the tangible benefits of automation in the manufacturing industry.

Retail Sector: Amazon

Amazon’s journey in automation is a model for the retail sector. To address challenges like order fulfillment speed and inventory management, Amazon leveraged technology through the implementation of automated warehouses. The use of robotic systems to pick and pack items has dramatically transformed the company’s logistics operations.

As a result of this automation, Amazon has reported faster delivery times, with many orders reaching customers within one day. The efficiency gained from these systems has also contributed to cost savings, allowing Amazon to maintain competitive pricing. The company reported a decrease in operational costs by over 20%, showcasing the direct impact of automation on profitability and customer satisfaction.

Healthcare Sector: Mount Sinai Health System

Mount Sinai Health System in New York City is a prime example of automation in healthcare. The organization faced challenges related to patient data management and administrative inefficiencies. To combat these issues, Mount Sinai implemented an automated electronic health record (EHR) system, which streamlined patient information processing.

The automation of EHRs resulted in improved data accuracy and reduced paperwork for healthcare professionals. The health system saw a 30% decrease in administrative time spent on patient records, which allowed clinicians to focus more on patient care. This shift not only improved operational efficiency but also enhanced the quality of care provided, leading to better patient outcomes and increased patient satisfaction.

Finance Sector: JPMorgan Chase

In the finance sector, JPMorgan Chase has successfully integrated automation to enhance its operations. The bank experienced challenges related to compliance and risk management processes that were traditionally labor-intensive. To address these issues, JPMorgan Chase implemented robotic process automation (RPA) for various back-office functions.

Through RPA, the bank automated tasks such as transaction reporting and compliance checks, resulting in faster processing times and reduced errors. The measurable impact included a 50% reduction in the time taken to complete compliance-related tasks and a significant decrease in operational costs. This automation allowed JPMorgan Chase to improve its service delivery while maintaining a high level of regulatory compliance.

“Automation is not just about reducing costs; it’s about enhancing productivity and improving service quality.”

The examples of Tesla, Amazon, Mount Sinai Health System, and JPMorgan Chase highlight the diverse applications of automation across different industries. Each case demonstrates the challenges faced, the innovative solutions implemented, and the positive outcomes achieved, reinforcing the critical role of automation in driving business success.

Automation and Sustainability Initiatives

Automation technologies play a pivotal role in enhancing sustainability across various sectors. By integrating advanced automation systems, companies can streamline operations, reduce waste, and foster eco-friendly practices. This not only helps businesses comply with environmental regulations but also promotes a positive corporate image, which is increasingly important in today’s market.

The impact of automation on sustainability is profound, particularly in areas such as waste reduction and resource management. By utilizing smart systems, organizations can monitor and optimize their resource consumption in real time. For example, manufacturing processes can be adjusted dynamically to minimize excess material use, while energy management systems can help factories reduce their carbon footprints.

Waste Reduction and Resource Management

Effective waste reduction and efficient resource management are crucial components of sustainable business practices. Automation facilitates these goals by providing precise control over production processes, which can lead to significant reductions in waste. Here are some key points regarding the role of automation in these areas:

- Smart manufacturing systems can analyze production data to identify inefficiencies, leading to a decrease in scrap materials. For instance, a major automotive manufacturer implemented robotics for precise material handling, resulting in a 20% reduction in waste.

- Automated inventory management systems help in reducing overstock and spoilage in retail and food industries. For example, a grocery chain used automated stock management, which cut food waste by 30% through timely inventory turnover.

- Energy-efficient automated processes, such as those found in smart grids, optimize energy consumption based on real-time demand, significantly lowering energy waste. A utility company that adopted automated demand response systems reported a 15% decrease in peak energy usage.

“Automation leads to sustainable production by minimizing waste and optimizing resource allocation.”

Successful green automation projects showcase the environmental benefits of these initiatives. Notably, in the agricultural sector, precision farming technologies are transforming traditional practices. Automated systems that use drones and IoT devices enable farmers to monitor crop health and soil conditions accurately. This data-driven approach reduces the need for fertilizers and pesticides, resulting in less chemical runoff and healthier ecosystems.

In addition, companies like Unilever have embraced automation in their manufacturing processes, achieving significant reductions in water usage and energy consumption. Through automated adjustments in their production lines, Unilever reported a decrease of 50% in water usage per product produced over a decade.

By leveraging automation, industries can move toward more sustainable practices, demonstrating a commitment to environmental stewardship while also realizing operational efficiencies.

The Challenges of Implementing Automation Strategies

Implementing automation strategies can streamline operations and enhance efficiency, but organizations often encounter various challenges along the way. Understanding these obstacles is crucial for a successful transition to automated systems. This discussion addresses common issues that arise during implementation and highlights the importance of workforce training and strategies for overcoming resistance to change.

Common Obstacles in Automation Implementation

Organizations frequently face several hurdles when integrating automation technologies. Identifying these challenges is crucial for devising effective solutions. The common obstacles include:

- Cost of Implementation: The initial investment for automation technologies can be significant, involving expenses related to software, hardware, and infrastructure upgrades. Organizations must carefully evaluate their budgets and potential ROI to justify these expenditures.

- Integration with Legacy Systems: Existing systems can pose a challenge during automation implementation. Many organizations operate on outdated technology that may not easily integrate with new automated solutions, resulting in additional costs and delays.

- Data Security Concerns: With automation comes the need to manage sensitive data. Organizations must address potential vulnerabilities that automated systems could introduce, prioritizing cybersecurity to protect against breaches.

- Lack of Skilled Workforce: The successful implementation of automation requires a workforce skilled in the new technologies. A skills gap can hinder progress and limit the effectiveness of the automation initiatives.

Importance of Workforce Training and Adaptation

As automation transforms workplaces, it is vital for organizations to focus on workforce training and adaptation. Employees need to develop new skills to work alongside automated systems effectively. This transition involves:

- Learning New Technologies: Ongoing training programs enable employees to familiarize themselves with automation tools and processes. This knowledge is critical to maximizing efficiency and productivity.

- Cultivating a Growth Mindset: Encouraging employees to embrace change and view automation as an opportunity for growth can foster a positive work environment. A culture that values continuous learning can ease the transition.

- Providing Support Resources: Offering resources such as workshops, mentorship programs, and online training modules can help employees adapt more effectively to new technologies.

Overcoming Resistance to Change

Resistance to change is a common reaction among employees when new technologies are introduced. To address this, organizations can adopt several strategies to facilitate smoother transitions:

- Effective Communication: Clearly communicating the reasons behind the automation initiatives can help alleviate fears and misconceptions. Transparency about the benefits can encourage buy-in from employees.

- Involving Employees in the Process: Engaging employees in the decision-making process can create a sense of ownership and commitment. Feedback mechanisms allow employees to express concerns and contribute ideas for the implementation process.

- Highlighting Success Stories: Sharing successful case studies and testimonials from other organizations that have embraced automation can inspire confidence and reduce apprehension toward change.

- Gradual Implementation: Implementing automation in stages allows employees to adjust gradually, reducing the overwhelming feeling that often accompanies large-scale changes.

Ending Remarks

In conclusion, Automation represents a pivotal force in shaping the future of industries and employment. As we navigate the challenges and opportunities it presents, embracing responsible integration and continual adaptation will be essential for maximizing its benefits and minimizing its risks.

Question Bank

What industries are most impacted by automation?

Manufacturing, retail, and transportation are among the sectors most significantly affected by automation, experiencing both job displacement and new opportunities.

How does automation affect job creation?

While automation can displace certain jobs, it also creates new roles that require different skills, often leading to a net increase in employment in tech-driven sectors.

What are some examples of successful automation?

Companies like Amazon and Tesla have successfully implemented automation to streamline operations and enhance productivity, showcasing tangible benefits.

Can automation contribute to sustainability?

Yes, automation can improve resource management and reduce waste, helping industries adopt more sustainable practices.

What are common obstacles to implementing automation?

Common challenges include resistance to change, workforce training needs, and the upfront costs associated with integrating new technologies.